Suspension Type Insulator

Suspended Type Insulators are generally made of insulating parts (e.g. porcelain, glass parts) and metal accessories (e.g. steel feet, iron caps, flanges, etc.) bonded with adhesive or mechanically clamped. Insulators are widely used in electric power systems, most of which are externally insulated and operate under atmospheric conditions.

ZMS can produce low, medium, and high voltage standard insulators made of epoxy resin, ceramic, polymer materials, and glass. We can manufacture any type of insulator product to meet your project requirements. Contact us today for more competitive pricing on polymer suspension insulators.

Types Of Suspension Insulator Products

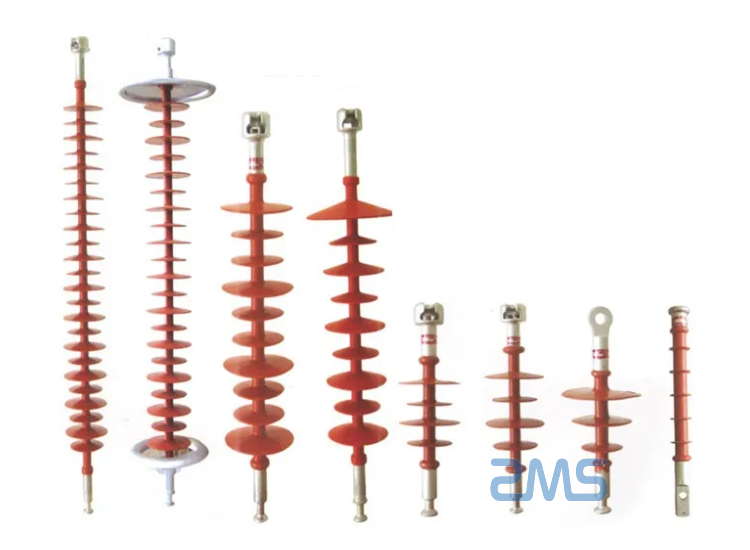

Polymer Suspension Insulators

Polymer suspension insulators are made from fiberglass epoxy mandrels, silicone rubber sheds, and metal fittings. Adopting international advanced-level pressure welding technology, it has high strength, beautiful contour, small volume, and is lightweight.

- Rated Voltage: 11KV-33KV

- Material: Polymer composite material

- Rod Material: fiber glass

- Tensile Strength: 70KN/120KN

- Standard: IEC61109

- Packing: carton

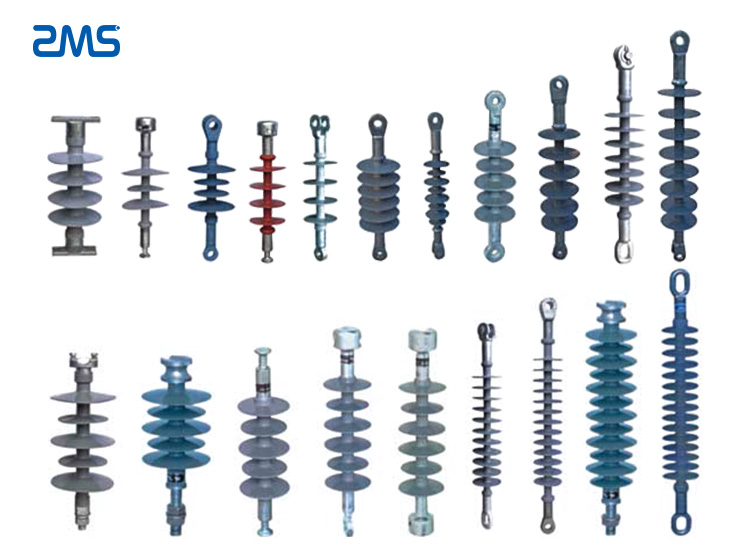

The porcelain suspension insulators are composed of a single or a string of insulating discs suspended from a tower. It operates at a voltage of 33kv or more. The insulator caps are made of high-density ductile iron and we test each cap by magnetic particle testing method. The overhead cable insulator pins are made of forged steel, a material that ensures that the interior of the pin is free of any defects such as air, holes, cracks, etc. Both caps and pins are hot-dips galvanized and the thickness of zinc conforms to ASTM 135.

We produce disc porcelain with high alumina porcelain C120, which is covered with a hard glaze, and the color can be gray, brown, white, or according to the customer’s requirements. The material of the R-lock pin is stainless steel, which guarantees a very secure insulator string connection.

We use excellent Portland cement to assemble the overhead line insulators with the associated caps and pins, and the cement remains good even after years of maintenance.

About Polymer Insulators and Ceramic Insulators

The Advantages of Polymer Insulators

- Strong anti-fouling flash synthetic insulator surface is water repellent, water is glistening on it, not easy to form conductive pathways, plus the small diameter of synthetic insulator umbrella disc, large creepage distance, high surface resistance, and small leakage current. Therefore, it has a high foul flash voltage.

- High strength and lightweight: Because of the high tensile strength of the rod core, the synthetic insulator can be made very light to reduce the force on the tower and save a lot of cost by reducing the installation and maintenance intensity.

- Good anti-aging properties: synthetic insulators have good corrosion resistance and anti-aging property, still have elasticity at 70℃, and can work for a long time at 20℃.

- Small volume and lightweight: Due to the small volume and light weight of synthetic insulators, and the flexible umbrella disc, they are not easy to break. Therefore, it brings great convenience to transportation, installation, and maintenance. Application of composite insulators, although the price is higher than porcelain insulators, from the long-term comprehensive economic benefits, the polymer insulator is the most ideal material. And the higher the voltage, the more obvious the economic benefits.

The Advantages of Porcelain Insulator

- More environmentally friendly: made of natural materials and can be landfilled with other wastes.

- Higher electrical strength: better electrical properties compared to polymers and longer service life in terms of charge-generated loads and other temporary electrical phenomena.

- High heat resistance and strength: withstands temperatures of up to 1000 °C, the surface is stabilized against UV radiation.

- Highly hardened surface: resistant to rodents, termites, birds and other animals capable of destroying the integrity of the polymer.

- Wide range of applications: contactors, disconnect switches, equipment transformers, capacitors, but also electromagnetic rings with extreme surfaces, atypical insulators (filters).

- Long service life: Ceramic insulators do not deform unless external forces are applied, guaranteeing a service life of up to 40 years.

- Customizable: products are available in a variety of shapes during the manufacturing process.

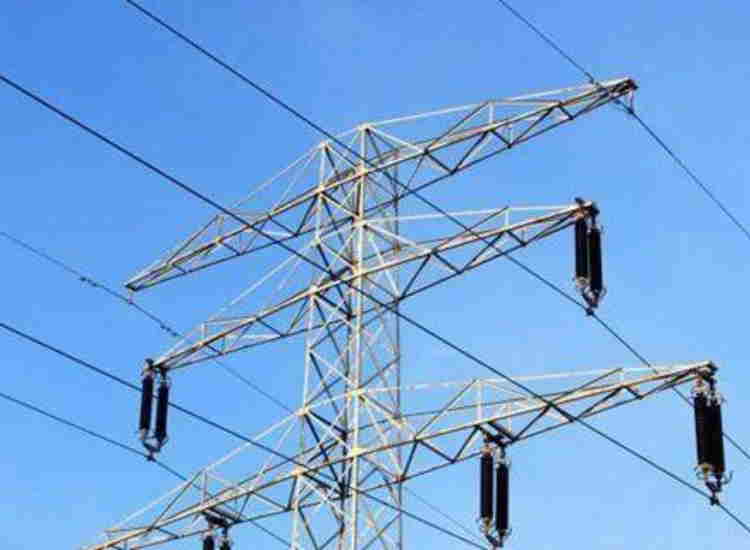

In general, overhead line insulators are designed to ensure good insulation between transmission fixed poles, transmission lines, parts of the transmission lines, and the earth. It is designed to avoid short circuits caused by the contact between the transmission line and the rest of the conductors during the transmission of electricity and has a pivotal role in electricity.

Types Of Overhead Line Suspension Insulators

The umbrella insulator is the oldest type of suspension insulator in use. It is characterized by its simple structure and shape, low cost, and is suitable for use in clean areas. They are usually used on AC transmission lines.

The disk-type suspension insulator is the most common and important type of line insulator in use. This cable insulator consists of an iron cap, insulating porcelain parts, and feet glued together with a cementitious adhesive.

This umbrella insulator has a long under-umbrella prong. The product can achieve a large creepage distance, the inner cavity under the umbrella is not easy to damp, and has a high fouling withstand voltage. It is more suitable for use on AC and DC transmission lines in coastal, foggy and humid, and saline areas.

This type has a particularly large diameter umbrella disc, a smooth, non-ribbed umbrella, a streamlined structure, good self-cleaning properties, and low dirt accumulation.

The use of characteristics is interspersed in the upper and middle of the overhead electric wire insulator dangling string of AC and DC lines, and the extra large disk diameter structure can play a role in inhibiting the occurrence of line dirt flashover caused by ice skating and bird droppings.

Service of ZMS Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.